Innovative Industrial Valves & Limescale Prevention Solutions

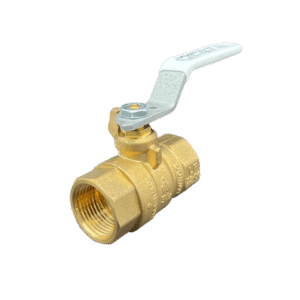

Elevate your industrial facility management with our comprehensive range of advanced valves and limescale prevention solutions. Our product lineup, including ScaleRx®, AVOS Thermoplastic Valves, American Valve’s 4000 Series™, MILANO® Ball Valves, and Signature HD Quarter Turn Valves, is engineered to address the most demanding fluid handling and limescale challenges.

A Solution for Every Water Problem

ScaleRx provides an innovative solution for limescale prevention, effectively protecting equipment without chemical alteration. AVOS Thermoplastic Valves offer exceptional chemical, abrasion, and corrosion resistance, ideal for a variety of industries. The 4000 Series by American Valve features a corrosion-resistant design, ensuring durable, efficient flow control. MILANO Ball Valves are known for their durability and precision, trusted in challenging service conditions. Signature HD Quarter Turn Valves ensure robust performance for hose and spray equipment connections, offering ease of use and durability.

Quote List

No products in the list

Harness Water with American Valve

Together, these product families represent the pinnacle of valve technology and limescale prevention, offering industrial facility managers a comprehensive, efficient, and reliable solution for managing their fluid handling systems. Ready to learn more about American Valve’s solutions?