Water & Wastewater Treatment Plant Valves and Scale Inhibitors

Industries Served

Have Questions?

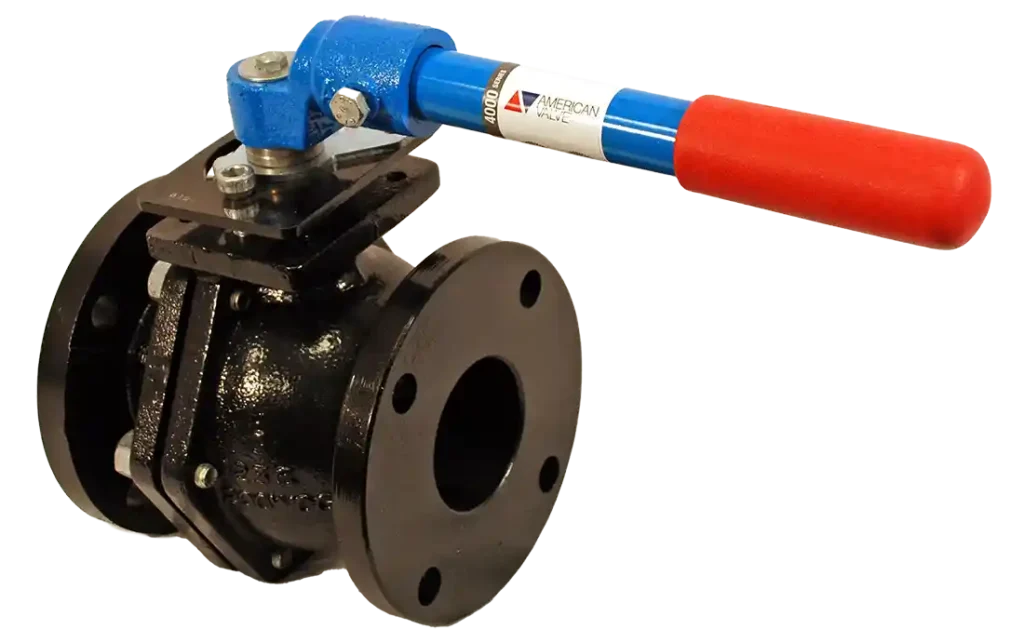

Avoid Downtime with4000 Series Ball Valves from American Valve

Replace Sticking Wastewater Valves

with 4000 Series Ball Valves

Eccentric plug valves are common in wastewater treatment plants, but they present challenges to operators. Their reduced port restricts flow, increasing turbulences and and collecting solids on the exposed seating surface. Most plug valves are left unpainted on the interior, making them susceptible to corrosion. As a single seat unidirectional valve, rebuilding or replacement is the only option to solve leaks. Further, if you’re looking to automate, plug valves aren’t a viable option.

Gate and Butterfly valves might be the only choice for large-diameter (>10”) pipes, but the inherent flaws of exposed seats lead to sticking and jams.

Upgrade to Reliability:

4000 Series Ball Valves from American Valve

One of the primary concerns with traditional valves lies in their susceptibility to leaks. Plug valves have obstructions and exposed seating surfaces that accumulate sludge and debris. Over time seals become compromised, leading to leaks and inefficiency. 4000 Series ball valves from American Valve are free of obstructions and feature a patented PFA*-fused solid metal ball. This means that you can trust these valves to maintain a positive shutoff, eliminating the risks associated with damaging leaks and expensive maintenance operations to “exercise” valves periodically.

The 4000 Series stands out for its reliable ease of operation, a crucial feature for water and wastewater operations teams who often need to make valve adjustments quickly. The non-stick lubricity of a PFA*-fused ball allows maintenance teams to act quickly and efficiently without the need of cheater bars or come-alongs to operate valves. This ease of use not only enhances the overall efficiency of your systems but also minimizes the downtime associated with maintenance tasks.

American Valve pioneered the process to fuse PFA* .008” into a solid metal ball, providing exceptional durability and resistance to corrosion even where acidic waste is present—a common reason for valve failure. With a cast iron ball used in a cast iron body and a stainless steel ball inside a ductile iron or stainless steel body, 4000 Series ball valves can be used in applications where thermal expansion causes dissimilar metals to fail.

4000 Series ball valves have the same flange dimensions, bolt patterns, and ANSI B16.10 end-to-end dimensions to seamlessly replace any 125/150 class eccentric plug or gate valve. The 4000 Series is also lighter and takes up less space. With a full port design, you won’t need to worry about flow restriction, providing a more efficient and modern solution tailored to the specific needs of water and wastewater management.

Upgrade your water or wastewater treatment facility with the confidence of positive shutoff and effortless quarter-turn operation. Trust American Valve’s 4000 Series ball valves and their patented PFA*-fused ball to deliver the reliability your facility demands, ensuring a secure and efficient operation that aligns with the highest standards of efficiency.

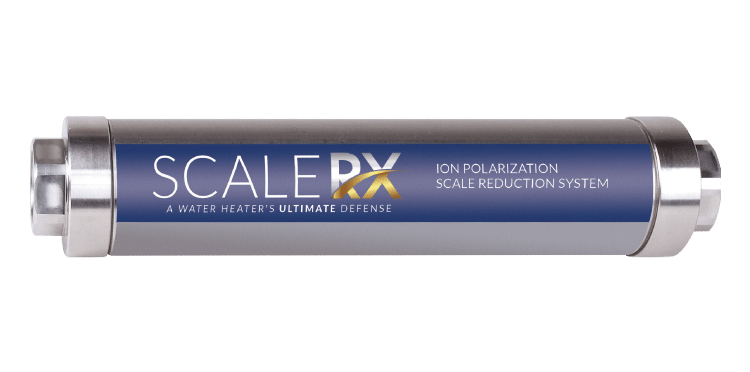

Protect Your Equipment and Gain Peace of Mind with ScaleRX

As a wastewater treatment plant superintendent, plant operator, or maintenance mechanic, you are likely to encounter challenges related to hard water and limescale buildup. These issues clog or jam your equipment and filters, limiting their efficiency. Limescale accumulation in heat exchangers, valves, strainers, and RO filters, requires costly maintenance and frequent replacement. Limescale leads to increased energy consumption and operational costs.

Traditional water softening systems usually aren’t an option in wastewater treatment plants. Salt discharges kill the bacteria needed to break down organic elements and nutrients. Water softeners also require regular maintenance that consumes massive amounts of fresh water. Enter ScaleRX®, American Valve’s innovative zero-maintenance scale inhibitor engineered to provide a robust defense against limescale deposits in filters and equipment.

Limescale Protection to Lower Costs

ScaleRX effectively addresses hard water problems by preventing limescale formation in your piping system and treatment equipment. By incorporating ScaleRX into your facility, you can significantly prolong the life of your wastewater management system, eliminate regular maintenance and operating expenses, and enhance energy efficiency.

Our water and wastewater treatment plant valve solutions complement ScaleRX, ensuring optimal water system performance while countering the adverse impact of hard water on valves and critical components. ScaleRX is a wise investment, promising both immediate ROI as well as long-term cost savings and contributing to a more sustainable and efficient plant management strategy.

Chemical Process Optimization

Chemicals used for coagulation, flocculation, pH adjustment, and other processes in your water or wastewater treatment facility are sensitive to changing conditions. Limescale can interfere with the effectiveness of these chemicals, leading to less efficient wastewater treatment, and ultimately creating more work for you.

Limescale buildup can also hinder the effectiveness of dosers, nozzles, and flow monitors that play a vital role in consistent chemical management. ScaleRX doesn’t filter or remove anything from water; it only prevents the formation of hard calcite crystals comprising limescale.